Case Study

Alternative energy sources for mobility including Natural Gas, Battery Modules and multiple types of Fuel Cells create nontraditional mounting schemes that need to perform as “flexible fasteners”.

- Dissimilar thermal expansion rates

- Large physical size/shape hole tolerance challenges

- Severe twisting and non-uniform road input accommodations

Thermal Expansion

The challenge with thermal expansion is the physical size of the alternative energy sources and the dissimilar thermal expansion rates that can create extremely high attachment point stresses.

Tolerance Challenges

Many of the alternative energy source are mounted across the frame rails or along the rails that require flexible attachment points to accommodate large tolerances, while still maintaining a “safetied” attachment.

Severe Road Inputs

Large battery modules and tanks can be severally damaged or leak from large non uniform road inputs including severe twist ditch type deflections. Elastomeric mounts can reduce these localized stresses.

The Solution!

Elastomeric/Rubber mounts can serve as “flexible fasteners” to mitigate thermal expansion, increased tolerances and large deflection inputs. In addition, they protect sensitive electronics by isolating random and predicted/expected shock and vibration inputs. Some examples are listed below.

Examples

Natural Gas tanks mounted to Class 7/8 truck rails

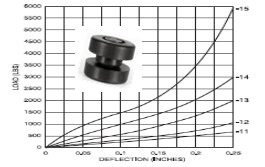

Frame Twist Events

Tolerance Accomodation, Safetied Attachment and Vibration Isolation Loading

Hutchinson is a leading supplier of shock, vibration, and motion accommodation to the global transportation market. We have been safely and securely mounting customers' payloads for 75 years. Bring us your problems and let us help you find a solution.

Quick Contact Form

The personal data collected are processed, the responsibility of which is HUTCHINSON AEROSPACE & INDUSTRY INC. company, in order to respond to your request for information and/or for the purpose of commercial prospecting. Mandatory fields to be completed are marked with an asterisk. The legal basis for the processing is your consent, which you may withdraw at any time, without prejudice to previous processing operations. Personal data are reserved for the use of the HUTCHINSON group and may only be transmitted to companies of the HUTCHINSON group and/or commercial partners for commercial purposes, if you have expressly consented to this.

In accordance with the regulation relating to personal data (GDPR), you have the right of access, rectification and erasure of your personal data, as well as the right of opposition to their processing. You may request the disclosure of your personal data and you have the right to define guidelines for the treatment of your personal data after your death. You can also request the portability of your data as well as the limitation of their processing, and/or file a complaint to your local authority.

You can exercise your rights and ask us about the processing of your personal data by contacting us at the following email address: [email protected]

To find out more read our Privacy and Cookies Policy.