Case Study

A Unique Challenge Requires a Custom Solution... or Does It?

Many customers come to us with the assumption that they’re looking for a custom part. What they do is unique. Perhaps they require materials that can withstand extreme temperatures or especially rough conditions. They’re not aware of any existing solutions to meet their challenge. When they call or email Hutchinson, they’re routed to our Engineering Services Group (ESG) to find a solution.

When the challenge is truly one-of-a-kind, our engineers go to work on R&D, prototyping, tooling and production of a custom solution. Given the costs associated with that process, however, we are sensitive to the fact that the ideal scenario for most customers is to find new applications for standard parts—and we have a catalog of over 5,000 that have the potential to fulfill their needs right off the shelf.

“We have the engineering expertise to understand their identified problem,” says Hutchinson Vehicle and Industrial Market Manager Nadine Akey. “We have the material expertise and knowledge of the environments these parts are going into. Whatever the issue—whether it’s vibration, noise or electronics that need to be isolated—we have over 5,000 parts we can choose from for a solution before deciding that it’s truly a custom project.”

Customizing Options to Meet Your Budget

When the need arises, we are always happy to design a custom part for a customer. We pride ourselves on having the international production capabilities to keep costs and lead times to an absolute minimum. We serve a diverse range of OEMs, in industries from Naval and Defense to Industrial, with major variations in budget. Of course, custom-designed parts require time and resources to research, develop and produce, so we offer a range of options through our domestic and international tool manufacturing capabilities to meet the customer’s budget.

When the need arises, we are always happy to design a custom part for a customer. We pride ourselves on having the international production capabilities to keep costs and lead times to an absolute minimum. We serve a diverse range of OEMs, in industries from Naval and Defense to Industrial, with major variations in budget. Of course, custom-designed parts require time and resources to research, develop and produce, so we offer a range of options through our domestic and international tool manufacturing capabilities to meet the customer’s budget.

Many customers are also interested in bringing the manufacturing and distribution of their products back to the U.S. after suffering through the supply chain disruptions caused by the COVID-19 pandemic. Some of our OEMs even tool at an alternate manufacturing location, qualify it, and then leave it on the shelf to be prepared should such a disruption occur again.

Creative Solutions, Standard Parts

Even so, tooling costs for a custom part can range anywhere from $5,000 to $50,000, and lead times can range up to 25 weeks in some cases. Clearly, OEMs are going to appreciate the most cost- and time-efficient solution, and in a surprising number of cases, that solution is to identify an existing part to meet the need. We’ll give you an example:

Even so, tooling costs for a custom part can range anywhere from $5,000 to $50,000, and lead times can range up to 25 weeks in some cases. Clearly, OEMs are going to appreciate the most cost- and time-efficient solution, and in a surprising number of cases, that solution is to identify an existing part to meet the need. We’ll give you an example:

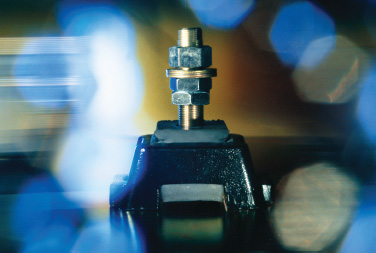

Our customer, a consulting company, had already installed our competitor’s vibration isolator in the concentrator’s pump system, but they were unhappy with its performance. After a quick theoretical analysis, we recommended using our commercial off-the-shelf (COTS) ball mount series vibration isolators in place of the competitor’s parts. Finding that our turnkey isolator would fit into their installation, the customer brought the system to our facility to measure the vibration and test our recommended isolator.

After installing accelerometers to record the pump’s vibrations, we reviewed the data and selected an isolator that would provide the desired performance. To nobody’s surprise, this isolator improved vibration reduction on the first try. We then fine- tuned our solution by implementing a ball mount of the same size and installation, but with a different stiffness of rubber—and achieved optimal results. The customer was thrilled with the final isolator, and we provided them with samples they could use to conduct further testing.

Ultimately, our COTS part reduced noise and vibration, which would help ensure comfort for patients who used the oxygen concentrator. The selected part was also much easier to install than the competitor’s and would increase the service life of the pump. The customer has since ordered 10,000 units of this isolator, and they expect this quantity to double annually.

If you are interested in learning more about our capabilities, or if you want to speak with us about your project, we’d love to connect. Reach out today to learn more.

Quick Contact Form

The personal data collected are processed, the responsibility of which is HUTCHINSON AEROSPACE & INDUSTRY INC. company, in order to respond to your request for information and/or for the purpose of commercial prospecting. Mandatory fields to be completed are marked with an asterisk. The legal basis for the processing is your consent, which you may withdraw at any time, without prejudice to previous processing operations. Personal data are reserved for the use of the HUTCHINSON group and may only be transmitted to companies of the HUTCHINSON group and/or commercial partners for commercial purposes, if you have expressly consented to this.

In accordance with the regulation relating to personal data (GDPR), you have the right of access, rectification and erasure of your personal data, as well as the right of opposition to their processing. You may request the disclosure of your personal data and you have the right to define guidelines for the treatment of your personal data after your death. You can also request the portability of your data as well as the limitation of their processing, and/or file a complaint to your local authority.

You can exercise your rights and ask us about the processing of your personal data by contacting us at the following email address: [email protected]

To find out more read our Privacy and Cookies Policy.

Innovating Solutions,

Building Trust

Hutchinson has an 80-year reputation to uphold—one that rests entirely on the relationships we build with our customers. They trust that we will work to find them a solution

that is well within or below their budget whenever possible, and while we certainly pride ourselves on our superior design innovation, we also take great satisfaction in innovating

fresh solutions from existing parts and materials. When our customers feel we have their backs, we know we’ve done our job.